#Supply Chain Risk Management Software Market

Explore tagged Tumblr posts

Text

#Supply Chain Risk Management Software Market#Logistic Management Solution#Supply Chain Risk Management Software Market size#Supplier Risk Management Solution#Supply Chain Risk Management Software industry#Supply Chain Risk Management Software Market share#Supply Chain Risk Management Software top 10 companies#Supply Chain Risk Management Software Market report#Supply Chain Risk Management Software industry outlook

0 notes

Text

Supply Chain Risk Management Software Market - Forecast(2024 - 2030)

Supply Chain Risk Management Software Market Overview

Supply Chain Risk Management Software market size was valued at $2.7 billion in 2020, and it is estimated to grow at a CAGR of 9.3% during 2021-2026. Adoption of supply chain risk management software in various industries such as manufacturing, transportation and logistics, pharmaceuticals, and food & beverages sectors drives the market, as this software assist industries in providing equilibrium between supply and demand. Supply chain management encompasses the integrated planning and execution of processes needed to optimize the flow of materials, information and financial capital in the areas that include demand planning, sourcing, production, inventory management and storage, transportation or logistics and return for excess or defective products. Adoption of this kind of supply chain risk management software assists in enhancing business processes in applications such as logistic management and enterprise risk management which helps to reduce supply chain risk. This will drive forward the supply chain risk management software industry.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐚𝐦𝐩𝐥𝐞

Supply Chain Risk Management Software Market Report Coverage

The report: “Supply Chain Risk Management Software Market Forecast (2021-2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the Supply Chain Risk Management Software industry.

By Deployment: On-Premise, Cloud By Type: Supplier Risk Management Solutions, Sustainable Procurement Solutions, Logistic Management Solutions By Industry Vertical: Consumer Goods, Transport & Logistics, Healthcare, Retail, Manufacturing, Food & Beverage, and Others By Geography: North America (U.S., Canada and Mexico); Europe (U.K., Germany, Italy, France, Rest of Europe); APAC (China, Japan, South Korea, India, Rest of APAC); South America (Brazil, Argentina, Rest of Americas); RoW (Middle East & Africa)

Key Takeaways

North America dominated the supply chain risk management software market in terms of value in 2020 owing to the early adoption of advanced software solutions and increase in investments.

Adoption of cloud deployment mode for supply chain risk management software implementation owing to its increased availability and high scalability drives the market.

Increasing adoption of supply chain risk management software in transport and logistics sector for logistic management with increasing government initiatives is set to drive the market.

Data security issues is one of the major challenges that hampers the market growth.

Supply Chain Risk Management Software Market Segment Analysis - By Type

Cloud Segment held the major share around 56.9% of global supply chain risk management software market in 2020. Cloud-based deployment allow industries to stay-up-to-date and aware with real time dashboard alerts. With this deployment, data can be synchronized seamlessly from multiple sources as it provides the ability to communicate and share data more easily than on-premise. Furthermore, ease of deployment, and pay per usage model have resulted in high adoption of cloud-based deployment.

Supply Chain Risk Management Software Market Segment Analysis - By Industry Vertical

Transport & Logistics is the fastest growing segment in Supply Chain Risk Management Software market and is estimated to grow at a CAGR 10.0% during forecast period 2021-2026. In this industry, adoption of supply chain risk management software for applications such as estimating shipment histories, demand forecasting, and freight in transit applications is poised to propel the market growth. The growth of the transport and logistics segment is attributed to globalization of supply chain and transport networks, which have given rise to supply chain risks such as lack of supplier visibility, extensive sub-contracting, natural disasters conflict and political unrest. Extensive subcontracting may lead to integrity related risks such as child labor or forced labor, unsafe workplace conditions, illegal worker payment. These factors have led the transport and logistics companies to focus on implementing supply chain risk management solutions in order to analyze risk or security assessment, failure mode and effects analysis, market condition, and map the supply chain resilience risk. Furthermore, several governments such as India, South Korea and others are focusing on adopting supply chain risk management solutions to identify, assess, and prioritize risks. The Government of India is undertaking significant steps to support the logistics sector. In 2019, Indian Commerce and Industry Ministry has granted a funding of $0.011k to the logistics sector for building initial infrastructure. This kind of initiative provides opportunities for the market growth.

Supply Chain Risk Management Software Market Segment Analysis - By Geography

North America dominated the Responsible Sourcing Software market in 2020 with a market share of 36.9%, followed by Europe and APAC owing to the early adoption of advanced digital technologies and high investments in adopting them. The presence of large number of manufacturing plants and big retail chains drives the adoption of supply chain risk management software. In 2018, The Federal Energy Regulatory Commission (FERC) of U.S., approved new mandatory reliability standards for protection of transportation and logistics equipment and to strengthen supply chain risk management in manufacturing industries. Stringent regulations in manufacturing industries and strict adherence to these regulations due to covid-19 impact in 2020 drive the market in this region.

#Supply Chain Risk Management Software market price#Supply Chain Risk Management Software market size#Supply Chain Risk Management Software market share

0 notes

Text

What is Freight Brokerage & Freight Forwarding Software

What is Freight brokerage and freight forwarding software?

Freight brokerage software allows a shipper to find carriers, manage the rates or tariffs as well as the contracts, and even track shipments. This eliminates the difficulties involved in the procedure and helps in making the admittance of new companies efficient as well as easy by automating these tasks. Freight forwarding software on another hand covers everything to do with shipping, from documents to storage and most importantly legal compliance with trade laws. Therefore, while brokerage software is primarily into matching shippers with carriers, forwarding is a software that handles the entire shipping process. Considering these disparities makes the functioning of transport brokers more effective and has a strong effect on the outcomes of their cooperation with clients.

Differences between Freight Forwarding & Freight Brokerage

Aspect

Freight Forwarding

Freight Brokerage

Primary Role

Manages the whole shipping process

Connects shippers with carriers

Physical Possession

Takes physical possession of the cargo

Does not take possession of the cargo

Services Provided

Handles documentation, storage, and transportation

Arranges transport contracts between shippers and carriers

Scope of Operations

Provides end-to-end logistics solutions

Focuses on negotiating and arranging transport

Customer Interaction

Simplifies trade regulations and logistics for businesses

Primarily negotiates and arranges transportation

Benefits of Using Freight Forwarding and Brokerage Software

Operational Efficiency

Freight forwarding and brokerage software significantly streamline operations, automating tasks such as load board management and carrier selection, which reduces manual efforts and enhances efficiency. Real-time tracking and automated notifications ensure smooth operational flow, minimising delays and errors.

Cost Savings

Implementing this software leads to direct cost savings by optimising route selection and reducing idle times, thereby cutting down on fuel and maintenance expenses. Automated invoice management and accurate rate calculations prevent financial discrepancies and reduce administrative costs.

Scalability

The software adapts to business growth, allowing easy integration of additional modules as needed. This flexibility supports expanding operational demands without the need for significant system overhauls, making it a future-proof investment.

Improved Tracking and Visibility

Advanced tracking features provide real-time data on shipments, enhancing visibility across the supply chain. This transparency helps in better managing expectations and reduces the risk of shipment delays.

Better Customer Service

Freight software enhances customer service by providing detailed tracking information and efficient issue resolution processes. This increases customer satisfaction and fosters loyalty.

Data Insights and Reporting

Comprehensive analytics tools offered by these software systems enable detailed performance monitoring and decision-making support. Insights gained from real-time data help in identifying inefficiencies and improving overall business strategies.

Conclusion

All these digital solutions are not only expected to improve flexibility in the operational processes but also to maximise cost efficiency and customer experience. To them they hold the potential of offering even more optimization, helping logistics specialists fine-tune solution provision. It’s important for organisations to adopt these technologies as they provide a competitive advantage through optimisation and valuable business intelligence. In this case, the integration of such systems is a business strategy well embraced by companies in the transport commission agent business due to ever changing market opportunities in the expanding global economy. Overall, the use of advanced freight software is not a trend but a revolution for FDI that opens the future of global logistics facilitating transnational business.

2 notes

·

View notes

Text

ERP in Manufacturing: What You Need to Know for Business Growth

In today's dynamic business landscape, manufacturing companies face numerous challenges, from volatile market demands to complex supply chain management. To thrive in this competitive environment, organizations are increasingly turning to Enterprise Resource Planning (ERP) systems. In this blog post, we will explore the significance of ERP systems for manufacturing companies, their role in software development companies, and the key factors that contribute to business growth.

Understanding ERP Systems for Manufacturing Companies

The Core of ERP: Integration and Automation

ERP systems are comprehensive software solutions designed to integrate and streamline various business processes within an organization. For manufacturing companies, ERP serves as a centralized platform that connects different departments such as production, inventory, procurement, finance, and human resources. The integration of these processes results in improved communication, data accuracy, and operational efficiency.

Key Features of ERP in Manufacturing

1. Production Planning and Scheduling:

ERP systems enable manufacturing companies to optimize production processes by providing real-time insights into resource availability, production capacity, and demand forecasting. This ensures that production schedules are aligned with market demands, reducing the risk of overproduction or stockouts.

2. Inventory Management:

Efficient inventory management is crucial for manufacturing companies. ERP software helps organizations maintain optimal inventory levels, minimize carrying costs, and prevent stockouts. It also facilitates better demand planning and order fulfillment.

3. Quality Control:

ERP systems play a vital role in maintaining product quality by tracking and managing every stage of the manufacturing process. This includes monitoring raw materials, production processes, and finished goods to ensure they meet industry standards and customer expectations.

4. Supply Chain Visibility:

With ERP, manufacturing companies gain better visibility into their supply chain. This visibility helps in identifying potential bottlenecks, reducing lead times, and enhancing collaboration with suppliers. A transparent supply chain is essential for meeting customer demands and maintaining a competitive edge.

5. Financial Management:

ERP systems provide robust financial modules that help manufacturing companies manage budgets, track costs, and generate accurate financial reports. This financial transparency enables informed decision-making and ensures compliance with regulatory requirements.

ERP for Software Development Companies: A Unique Perspective

While traditionally associated with manufacturing, ERP systems have found their way into software development companies as well. The principles of integration, automation, and streamlined processes are just as applicable in the software industry.

Project Management and Collaboration

In software development, ERP systems assist in project management by centralizing tasks, timelines, and resource allocation. This ensures that development teams work cohesively, deadlines are met, and resources are utilized efficiently. Collaboration is enhanced through shared data and communication channels, leading to improved project outcomes.

Resource Allocation and Time Tracking

ERP software allows software development companies to optimize resource allocation and track time spent on different projects. This data-driven approach enhances project planning, improves resource efficiency, and provides insights for future capacity planning.

Scalability and Flexibility

Software companies often face rapidly changing project scopes and client requirements. ERP systems provide the scalability and flexibility needed to adapt to these changes seamlessly. Whether it's adding new features, accommodating changes in project timelines, or expanding the scope, ERP systems empower software development companies to stay agile.

Key Considerations for Implementing ERP in Manufacturing

1. Customization and Flexibility:

Manufacturing companies should look for ERP solutions that offer customization options to align with specific industry needs. Flexibility is crucial, considering the diverse manufacturing processes and business models.

2. User Training and Change Management:

Successful ERP implementation requires thorough training of users and effective change management strategies. Employees need to understand the benefits of ERP and be comfortable with the new system to ensure smooth adoption.

3. Data Security and Compliance:

Given the sensitive nature of manufacturing data, security is a top priority. ERP systems must comply with industry regulations and provide robust security features to safeguard intellectual property, customer information, and business-critical data.

4. Integration with Existing Systems:

Seamless integration with existing software and systems is essential for a smooth transition to ERP. Compatibility with other tools and technologies ensures that there is no disruption in day-to-day operations during the implementation phase.

5. Scalability for Future Growth:

An ERP system should be scalable to accommodate the growing needs of a manufacturing company. It should support expansion into new markets, additional product lines, and increased production volumes without compromising performance.

Conclusion: Driving Business Growth with ERP

In conclusion, ERP systems have become indispensable tools for manufacturing companies seeking sustainable growth in a competitive market. By integrating and automating core business processes, ERP not only enhances operational efficiency but also provides valuable insights for strategic decision-making.

For software development companies, the adaptability of ERP systems offers a unique advantage in managing the dynamic and ever-evolving nature of the industry. The principles that make ERP effective in manufacturing—integration, automation, and streamlined processes—are equally applicable and beneficial in the software development landscape.

As businesses continue to evolve, embracing ERP is not just a technological choice; it's a strategic one. Those who invest in robust ERP solutions position themselves for improved competitiveness, increased profitability, and sustainable growth in the long run.

#ERP systems for manufacturing companies#ERP for manufacturing companies#ERP for software development company#ERP software for manufacturing companies#India#Gujarat#Vadodara#ERP India#Business Solutions#manufacurer#ERP software

7 notes

·

View notes

Text

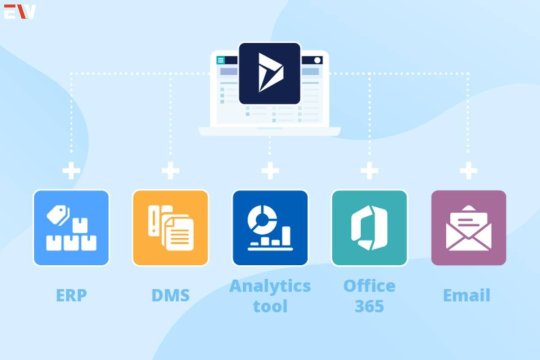

VisionSoftware offers seamless integration of various business processes into a single unified system. This integration includes accounting, human resources, supply chain management, and customer relationship management. By consolidating all these functions, VisionSoftware ensures that all departments within an organization can communicate and share information effortlessly. This unified approach not only improves efficiency but also reduces the risk of errors and data redundancy. As a result, businesses can operate more smoothly, make informed decisions, and respond to market changes more swiftly.

2 notes

·

View notes

Text

Larry Savage Birmingham About Logistics Challenges And How To Overcome Them

Logistics managers are now more aware of the need to obtain vital information instantly due to the pandemic. Additionally, it encouraged warehouse managers to be proactive in mitigating risks related to supply and demand. Today, machine learning software that analyzes real-time data can help prevent both overstock and out-of-stock. This is similar to IoT sensors assisting transportation businesses in tracking goods throughout the route. So, to learn more, read Larry Savage Jr Birmingham – Challenges That Necessitate The Need For An Organized Logistics Industry to level up your business performance.

Strengthen communication at all levels

A vital component of surviving in business is anticipating logistical obstacles and knowing how to overcome them. You should include improving communication with the participants in your global supply chain in your planning. You might even wish to create connections with far-off logistical companies to increase your marketing reach if your company is local. In order to stay informed about the state of the resources supporting your products and market, it's critical to keep in constant contact with your suppliers.

Establish standards for suppliers and partners

If businesses follow different standards, it could confuse some of them when arranging many deliveries daily with several supply chain managers. Logistics operations are considerably more streamlined and coherent when every service follows the same loading and unloading procedures. Supply chain visibility can also be maximized for all participants in this coordination through smart technology and interconnected electronic networks.

Invest in the right technology

Companies today are also overspending on the latest software and hardware developments due to the quick changes in business technology. Spending less on technology to achieve maximum efficiency is now possible if you use cloud technologies.

If your business is operating on a tight budget, cloud services offer the most economical options. A warehouse might think about collaborating with logistics industry specialists if it needs additional flexibility, scalability, or experience.

Using third-party logistics providers to carry goods to markets is one way for businesses that can't afford to invest in creating a logistics service that makes use of automation, robots, and artificial intelligence.

Reduce warehouse management errors

An infrastructure's likelihood of errors decreases as it becomes more digital through automation or improved access to pertinent real-time data.

Adopting warehouse management software with integrations to new and innovative technologies like 5G, AI, and IoT has become crucial in this century. You can use these technologies to gather and archive important logistics data.

Proper placement of warehouse inventory products is also crucial to avoid a cascade of disruptions.

Then, to prepare items for delivery, they must be carefully chosen and packed. Incomplete orders and incorrect delivery information are two common order fulfillment mistakes that still happen. Warehouse managers can effectively decrease these errors by using more vigilant supervision and enhanced picking and packing confirmation protocols.

Final thoughts

In the future, meeting customer needs will be the hardest task for the logistics industry. So, improving warehouse structure and layout by analyzing logistics will help you. Lastly, don’t read Larry Savage Birmingham — Know About The Basics Of Stock Options Trading to keep your fortunes thriving.

#Larry Savage Birmingham#Logistics Challenges#Logistics Expert#Logistics Industry#business owner#business ideas#business strategy

3 notes

·

View notes

Text

Supply Chain 2.0: The Evolution of Logistics in the Australian Business Landscape

Introduction: In the dynamic landscape of Australian business, the evolution of supply chain management has reached new heights with the advent of Supply Chain 2.0. This transformative phase is driven by advanced technologies and innovative solutions that redefine how businesses handle logistics. In this blog post, we will explore the changing face of Supply chain solutions in Australia, focusing on supply chain solutions and the role of supply chain management software in this transformative journey.

The Current State of Supply Chain Management in Australia:

Australia's geographical expanse and its position as a global trade hub make efficient supply chain management crucial for businesses. Traditional supply chain models are no longer sufficient to meet the demands of modern commerce. Companies across industries are recognizing the need to adapt and embrace Supply Chain 2.0 to stay competitive in today's fast-paced business environment.

Supply Chain Solutions in Australia:

Supply chain solutions play a pivotal role in enhancing the efficiency, visibility, and overall performance of logistics networks. Companies are increasingly turning to comprehensive supply chain solutions to optimize their operations. From procurement to distribution, these solutions streamline processes, reduce costs, and improve customer satisfaction.

One of the key drivers of Supply Chain 2.0 in Australia is the integration of cutting-edge technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT). These technologies empower businesses to make data-driven decisions, predict demand, and proactively address potential disruptions.

Supply Chain Management Software in Australia:

Central to the evolution of Supply Chain 2.0 is the adoption of advanced supply chain management software. In Australia, businesses are investing in sophisticated software solutions that offer end-to-end visibility and control over the entire supply chain. This software provides real-time insights, enabling companies to make informed decisions and quickly respond to changing market conditions.

The implementation of supply chain management software in Australia is not limited to large enterprises. Small and medium-sized businesses are also recognizing the benefits of digitizing their supply chain processes. Cloud-based solutions make these technologies accessible to businesses of all sizes, leveling the playing field and fostering innovation across the industry.

Benefits of Supply Chain 2.0 in Australia:

Increased Efficiency : Supply Chain 2.0 emphasizes automation and optimization, leading to increased efficiency in operations. From inventory management to order fulfillment, businesses can streamline processes and reduce the risk of errors.

Enhanced Visibility: Real-time data and analytics provided by supply chain management software offer unparalleled visibility into the entire supply chain. This visibility enables businesses to track shipments, monitor inventory levels, and identify potential bottlenecks.

Cost Reduction: By optimizing processes and minimizing inefficiencies, Supply Chain 2.0 helps businesses reduce overall operational costs. This cost-effectiveness is a significant factor driving the adoption of advanced supply chain solutions in Australia.

Adaptability to Market Changes : The dynamic nature of the business landscape requires companies to be agile and responsive. Supply chain management software allows businesses to adapt quickly to market changes, ensuring they stay ahead of the competition.

Final Thoughts :

As Australia embraces Supply Chain 2.0, the evolution of logistics is reshaping the way businesses manage their supply chains. The VNC Global integration of advanced supply chain solutions and management software is propelling the industry toward greater efficiency, visibility, and adaptability. Companies that invest in these technologies are better positioned to navigate the complexities of the modern business landscape, making Supply Chain 2.0 a key enabler of success in the Australian market. To stay competitive, businesses of all sizes must consider adopting these innovative solutions to unlock the full potential of their supply chains.

2 notes

·

View notes

Text

The Crucial ERP System Examples: Transforming Business Operations

In today’s fiercely competitive business realm, the quest for operational efficiency and streamlined management is paramount. Enterprise Resource Planning (ERP) systems stand tall as technological marvels, revolutionizing the way businesses operate. These robust software solutions amalgamate various functions within a unified framework, enabling seamless coordination across departments and facilitating data-driven decision-making.

This exploration ventures into the realm of ERP systems, shedding light on a spectrum of exemplary solutions that have reshaped modern business operations. From stalwarts like SAP ERP and Oracle ERP Cloud to innovative players like Microsoft Dynamics 365 and Odoo, each system represents a unique amalgamation of features, functionalities, and industry applications.

This comprehensive journey traverses the functionalities, industry adaptability, and transformative potentials of these ERP systems. Understanding their intricacies is pivotal for businesses seeking to optimize processes, unlock efficiencies, and navigate the complexities of today’s business landscape. Join this insightful exploration to unravel the significance and impact of these ERP system examples in shaping the future of business operations.

ERP System Examples

1. SAP ERP: Revolutionizing Business Management

SAP ERP has solidified its position as a leader by providing an all-encompassing suite covering critical business functions. Beyond its core modules in finance, HR, and supply chain, SAP offers specialized applications for industry-specific needs. For instance, SAP S/4HANA, an intelligent ERP, integrates AI and analytics for real-time insights, empowering businesses to adapt swiftly to market changes.

The scalability of SAP ERP is noteworthy, catering to startups aiming for growth and global corporations managing complex operations. It provides modular solutions, enabling businesses to adopt specific functionalities based on their immediate needs.

2. Oracle ERP Cloud: Innovating Operations in the Cloud

Oracle ERP Cloud’s robust suite extends far beyond traditional ERP capabilities. It embraces emerging technologies like AI, machine learning, and blockchain to drive innovation. Its predictive analytics empower businesses to anticipate market trends, optimize supply chains, and mitigate risks effectively.

The cloud-based structure of Oracle ERP Cloud ensures not just accessibility but also scalability without compromising security. It enables seamless integration with other Oracle Cloud applications, fostering a unified ecosystem for comprehensive business management.

3. Microsoft Dynamics 365: Integrating CRM and ERP Capabilities

Microsoft Dynamics 365 is a fusion of CRM and ERP functionalities, providing a holistic platform for businesses. Unlike its core ERP modules, Dynamics 365 offers advanced tools for customer engagement, field service, and marketing automation. Its flexibility lies in its modularity, allowing businesses to tailor their systems by choosing specific applications that align with their objectives.

Moreover, its integration with Microsoft Office 365 and Power Platform strengthens collaboration and data analysis, facilitating informed decision-making across departments.

4. NetSuite: Empowering Diverse Industries

NetSuite’s cloud-based ERP system addresses the complex needs of various industries. Its suite encompasses solutions for financial management, e-commerce, and inventory control. Beyond the core ERP functionalities, NetSuite offers industry-specific modules, such as SuiteCommerce for retail businesses and SuiteSuccess for services, enhancing its appeal across diverse sectors.

The scalability and adaptability of NetSuite make it a preferred choice for businesses experiencing rapid growth or seeking to expand into new markets.

5. Infor ERP: Tailored Solutions for Specific Sectors

Infor’s industry-specific ERP solutions cater to the nuanced requirements of sectors like healthcare, manufacturing, and distribution. In addition to its standard ERP functionalities, Infor focuses on specialized applications such as Infor CloudSuite Healthcare for healthcare organizations and Infor LN for manufacturing, ensuring tailored solutions for sector-specific challenges.

Infor’s commitment to innovation and addressing sector-specific complexities underscores its relevance in the ERP landscape.

6. Epicor ERP: Amplifying Industry Operations

Epicor ERP excels in catering to industries such as manufacturing, distribution, retail, and services. Its core ERP functionalities are complemented by advanced analytics and business intelligence tools. Epicor’s Smart Inventory Planning and Optimization (IPO) tool, for instance, utilizes AI to enhance inventory management, improving efficiency and reducing costs.

Moreover, its agile architecture enables easy customization and integration with third-party applications, providing businesses with a highly adaptable solution.

7. Odoo: Flexibility and Customization

Odoo’s open-source ERP system offers an extensive suite of applications covering CRM, inventory management, project management, and more. What sets Odoo apart is its modular nature, allowing businesses to select and integrate specific applications as per their requirements. Odoo’s flexibility and affordability are especially beneficial for small to medium-sized enterprises seeking customizable solutions without exorbitant costs.

The Value of ERP Systems in Modern Business

ERP systems serve as catalysts for efficiency, productivity, and growth:

Streamlined Operations: Automating tasks streamlines processes, reducing manual errors and optimizing resource allocation.

Enhanced Data Management: Centralized databases ensure data consistency and accuracy, fostering informed decision-making.

Agile Decision-Making: Real-time data access empowers businesses to make agile decisions, staying ahead in dynamic markets.

Customer-Centric Approach: Integrated CRM functionalities enable businesses to deliver personalized services, boosting customer satisfaction and loyalty.

Making Informed Choices: Selecting the Right ERP System

The process of choosing an ERP system involves careful evaluation and alignment with a business’s unique needs. Understanding the scalability, integration capabilities, and industry-specific functionalities of each system is crucial for successful adoption.

Conclusion: Embracing ERP Systems for Sustainable Growth

The landscape of ERP systems continues to evolve, offering businesses versatile solutions to streamline operations, enhance efficiency, and foster sustainable growth. From SAP’s scalability to Oracle’s cloud-driven innovation and Odoo’s customization prowess, each system exemplifies the diverse capabilities shaping modern business management.

Selecting the right ERP system aligned with specific needs remains pivotal for organizations seeking resilience and competitiveness. As businesses strive for optimization and adaptability, embracing these transformative technologies ensures a strategic advantage in an ever-evolving market. It stands as a pillar of efficiency, empowering businesses to navigate complexities and drive success through informed decisions and streamlined operations.

Also Read: A Deep Dive into Corporate Wellness Programs for a Healthier, Happier Workplace

#ERPRevolution#BusinessTransformation#TechInnovation#DigitalTransformation#EnterpriseSolutions#InnovationInBusiness#TechLeadership

2 notes

·

View notes

Text

Achieving Cost Savings through Supplier Collaboration in Siemens Teamcenter PLM Software

In the dynamic landscape of modern business, collaboration is the cornerstone of success. This holds true not only within an organization but also across the entire supply chain. Suppliers play a pivotal role in the journey from concept to creation, and their collaboration can yield significant cost savings and operational efficiencies. Teamcenter PLM's supplier collaboration features are transforming the way organizations interact with suppliers, leading to negotiated cost savings, improved procurement processes, and enhanced cost control. In this article, we delve into how Teamcenter PLM is fostering this collaborative spirit, backed by real-world examples.

A New Paradigm in Supplier Collaboration

Gone are the days of transactional relationships between organizations and suppliers. The modern approach is based on collaboration, where suppliers are viewed as strategic partners integral to the success of a project. Siemens PLM Software, with its comprehensive suite of supplier collaboration tools, empowers organizations to seamlessly integrate suppliers into their product development processes.

Negotiated Cost Savings: A Win-Win Scenario

Supplier collaboration in Teamcenter PLM opens the door to negotiated cost savings. When suppliers are brought into the design phase, they can offer valuable insights into cost-effective materials, manufacturing processes, and alternative components. By tapping into their expertise, organizations can optimize designs for cost efficiency without compromising on quality. For instance, a manufacturer collaborating with a supplier might identify a more cost-effective yet equally durable material for a component, resulting in substantial cost savings over the product's lifecycle.

Improved Procurement Processes: Streamlining Efficiency

Procurement is a critical component of the supply chain, and any inefficiencies can lead to increased costs. Teamcenter PLM's Cost Management Software supplier collaboration features streamline procurement processes by providing real-time visibility into supplier capabilities, capacities, and lead times. This enables organizations to make informed decisions about sourcing, reducing the risk of delays and costly last-minute changes. For instance, a company collaborating with a supplier can receive updates on raw material availability, helping them plan their production schedule and avoid costly supply shortages.

Enhanced Cost Control: Data-Driven Insights

Effective cost control requires accurate and up-to-date information. Teamcenter PLM's supplier collaboration features enable organizations to access real-time cost data from suppliers. This transparency empowers procurement teams to make strategic decisions based on actual costs rather than estimates. Furthermore, collaboration with suppliers can help organizations identify cost drivers and areas where cost reductions can be implemented. For instance, a company working closely with a supplier might discover opportunities to consolidate shipments, reducing transportation costs.

Real-World Examples of Success

Real-world examples illustrate the power of supplier collaboration in achieving cost savings. Consider a consumer electronics company partnering with a supplier to design a new smartphone. By collaborating closely, they identify a more cost-effective battery design that doesn't compromise on performance. This leads to reduced manufacturing costs and a competitive edge in the market.

In the automotive industry, a car manufacturer collaborates with a supplier of advanced materials. Together, they explore innovative materials that are not only lightweight but also cost-efficient. This collaboration results in cost savings due to reduced material consumption and improved fuel efficiency in the final product.

Conclusion: Empowering Future Success

Supplier collaboration through Teamcenter PLM software transcends traditional boundaries. It's a strategy that fosters innovation, efficiency, and cost savings. By involving suppliers early in the product development process, organizations can tap into their expertise, optimize designs, and make informed decisions that positively impact the bottom line. As the business landscape continues to evolve, organizations that embrace supplier collaboration are not only achieving cost savings but also laying the foundation for future success and growth.

For Free PLM Software trial, download Siemens Teamcenter PLM software trial!

#plmsoftware#costmanagementsoftware#what is plm software#plm software#siemens plm software#cost reduction software#free plm software

2 notes

·

View notes

Text

Top 10 Manufacturing ERP Systems in 2025

The manufacturing industry is evolving rapidly, and businesses must leverage advanced technology to stay competitive. Manufacturing ERP (Enterprise Resource Planning) systems play a crucial role in integrating business functions, improving decision-making, and streamlining operations. In 2025, AI-powered ERP solutions will continue to dominate, helping manufacturers optimize production planning, inventory management, and supply chain operations. This article explores the Top 10 Manufacturing ERP Systems in 2025, highlighting their unique features, AI capabilities, and how they empower manufacturers to scale efficiently. What is Manufacturing ERP Software? Manufacturing ERP software is a business management system designed to integrate and optimize production, inventory, supply chain, and customer management processes. These systems offer real-time data insights, AI-driven automation, and cloud-based accessibility, helping manufacturers improve efficiency and profitability. Benefits of ERP for Manufacturing Businesses Implementing an ERP system offers several advantages: • Automation & Productivity: Reduces manual tasks and redundancies • Optimized Inventory Management: Ensures accurate material planning • Supply Chain Visibility: Enhances procurement and logistics management • Regulatory Compliance: Minimizes risks with better tracking • Improved Customer Satisfaction: Accelerates order fulfillment • Data-Driven Decision Making: Provides real-time insights for better forecasting • Scalability: Adapts to market changes and business growth Things to Consider When Choosing an ERP System Selecting the right ERP system is critical for operational efficiency. Key considerations include: • Industry Experience: Choose an ERP with a proven track record in manufacturing • Customization & Flexibility: The system should adapt to unique business needs • Cost Considerations: Assess licensing, implementation, and maintenance costs • Cloud vs. On-Premise: Determine which deployment model fits your business • Integration Capabilities: Ensure compatibility with existing systems Best ERP Features for Manufacturing Modern manufacturing ERP systems offer features such as: • Production Planning & Scheduling: Aligns production with orders and capacity • Workflow Automation: Enhances quality control and equipment maintenance • Shop Floor Execution: Real-time tracking of labor, materials, and machines • Inventory Optimization: Uses AI-driven reordering and planning • Smart Factory Integration: Connects with IoT devices for real-time monitoring Top 10 Manufacturing ERP Systems in 2025

Microsoft Dynamics 365 Business Central A cloud-based ERP for SMBs, offering real-time data insights, AI-driven automation, and seamless integration with Microsoft tools. • Key Features: Production scheduling, financial management, inventory control • Why Choose It? Scalable, cost-effective, and cloud-accessible

NetSuite ERP A robust cloud ERP with strong financial, supply chain, and order management features, ideal for mid-sized manufacturers. • Key Features: Advanced planning, inventory tracking, financial reporting • Why Choose It? Scalable and mobile-friendly with AI-driven insights

SAP S/4HANA A feature-rich ERP with powerful AI capabilities, predictive analytics, and automation for large manufacturers. • Key Features: MRP optimization, machine learning, financial management • Why Choose It? Best for complex manufacturing operations

Oracle ERP A comprehensive cloud ERP offering supply chain, production, finance, and customer management functionalities. • Key Features: AI-driven demand forecasting, financial analytics, HR management • Why Choose It? Ideal for large enterprises with complex needs

Acumatica Cloud ERP A flexible cloud ERP designed for SMBs, integrating accounting, inventory control, and production management. • Key Features: Automated reporting, supply-demand balancing, real-time tracking • Why Choose It? Cost-effective and user-friendly

Infor Manufacturing Cloud ERP A scalable, AI-powered ERP that streamlines operations with cloud-based architecture and industry-specific solutions. • Key Features: Smart inventory, AI-driven analytics, real-time insights • Why Choose It? Secure, adaptable, and easy to integrate

Epicor Kinetic A cloud-based ERP with deep manufacturing capabilities, integrating IIoT and real-time shop floor data. • Key Features: MES software, AI-powered automation, advanced scheduling • Why Choose It? Ideal for manufacturers looking for real-time analytics

IFS Cloud A flexible ERP designed for project-based and field-service-heavy manufacturers. • Key Features: Asset management, service management, supply chain integration • Why Choose It? Best for complex project-driven manufacturing

SYSPRO ERP A hybrid ERP with strong production scheduling, traceability, and AI-powered analytics. • Key Features: Cloud, on-premise, or hybrid deployment, AI-driven forecasting • Why Choose It? Highly customizable with industry-specific solutions

Infor VISUAL ERP A user-friendly ERP that covers the entire manufacturing lifecycle, from planning to quality control. • Key Features: Shop floor automation, inventory management, financials • Why Choose It? Best for manufacturers needing end-to-end visibility Conclusion Manufacturers in 2025 need ERP systems that go beyond basic automation. AI-driven insights, cloud accessibility, and seamless integration with smart factory technologies make ERP a game-changer for business efficiency. Why Choose VLC Solutions? At VLC Solutions, we specialize in Microsoft Dynamics 365 Business Central implementation and customization. Our experts ensure a seamless ERP experience tailored to your manufacturing needs. Ready to optimize your manufacturing operations? Contact VLC Solutions today to find the right ERP for your business!

0 notes

Text

Livestock Monitoring Market Growth Analysis and Size Projection by 2025

Global Livestock Monitoring Market: Growth, Trends, and Forecast (2021–2027)

Introduction

The global Livestock Monitoring Market is witnessing rapid growth, fueled by increasing demand for automated monitoring systems that enhance productivity and animal welfare. With the rising adoption of smart farming solutions, precision livestock monitoring is gaining traction as farmers and agribusinesses seek efficient ways to manage livestock, optimize resources, and improve yields.

The market size was estimated at XXX million USD in the period 2016–2020, growing at a CAGR of XX%. It is expected to reach XXX million USD by 2021 and continue expanding at a CAGR of XX% from 2021 to 2027. The increasing need for data-driven livestock management, real-time health monitoring, and automation in dairy and meat production is driving this growth.

This report provides an in-depth analysis of the livestock monitoring industry, covering its industry chain structure, market environment, product segmentation, key market players, competitive landscape, pricing trends, and value chain dynamics.

Get free sample copy @ https://www.statsandresearch.com/request-sample/26406-global-livestock-monitoring-market

Market Dynamics

Key Drivers of the Livestock Monitoring Market

Growing Demand for Precision Livestock Farming

Farmers are adopting advanced technologies such as IoT sensors, AI-based monitoring, and automated feeding systems to enhance livestock productivity and welfare.

Precision farming helps in real-time tracking of animal health, movement, and nutrition, reducing the risk of disease outbreaks.

Rising Adoption of Automated Livestock Management Solutions

The use of automated milking, feeding, and breeding systems is growing, driven by labor shortages and cost optimization.

Technologies like RFID tags, GPS trackers, and smart sensors enable better livestock monitoring, performance tracking, and early disease detection.

Increasing Focus on Animal Health and Welfare

Government regulations and consumer awareness regarding animal welfare and disease prevention are pushing farmers to adopt health monitoring solutions.

Early detection of diseases through biometric sensors and AI-powered diagnostics minimizes losses and enhances farm profitability.

Integration of AI, IoT, and Big Data in Livestock Monitoring

Smart farming solutions leverage AI-driven predictive analytics, machine learning, and real-time IoT data collection to optimize herd management.

Cloud-based software platforms enable farmers to monitor livestock remotely, improving decision-making.

Growing Investments in Agri-Tech and Smart Farming Solutions

Increased funding and government support for digital farming technologies are accelerating the adoption of livestock monitoring solutions

Challenges in the Livestock Monitoring Market

High Initial Investment and Maintenance Costs

Advanced livestock monitoring systems require significant capital investment, which can be a barrier for small and medium-sized farmers.

Maintenance costs for smart sensors, data processing software, and automated machinery add to overall farm expenses.

Limited Technical Expertise and Awareness

Many farmers, especially in developing regions, lack the technical knowledge to effectively utilize AI, IoT, and data analytics for livestock management.

Connectivity and Infrastructure Constraints

Remote farming areas often face challenges related to internet connectivity, data transmission, and power supply, limiting the effectiveness of real-time livestock tracking systems.

Market Segmentation

By Product Type

The livestock monitoring market is segmented based on hardware, software, and services.

Hardware

RFID Tags & Sensors

GPS & Wearable Trackers

Smart Cameras & Surveillance Systems

Market Insight: Hardware components, including wearable health sensors, smart collars, and automated feeding systems, dominate the market due to their role in real-time livestock tracking and disease prevention.

Software

Cloud-Based Livestock Management Platforms

AI-Powered Health Monitoring & Analytics

Market Insight: AI-driven software solutions are gaining popularity, enabling predictive analytics, performance monitoring, and early disease detection.

Services

Consulting & Integration

Maintenance & Support

Market Insight: The service segment is expanding, driven by the need for customized farm management solutions and ongoing tech support.

Get full report @ https://www.statsandresearch.com/report/26406-global-livestock-monitoring-market/

By Application

Milk Harvesting

Automated milking systems improve efficiency, milk yield, and hygiene standards.

Feeding Management

Precision feeding technologies optimize nutrition, reduce waste, and enhance livestock growth.

Breeding Management

AI-based breeding solutions help in heat detection, fertility tracking, and genetic improvement.

Behavior Monitoring & Control

AI-powered wearables and sensors monitor livestock movement, stress levels, and unusual behavior, preventing injuries and diseases.

By Region

North America (U.S., Canada, Mexico)

Market Leader due to the presence of advanced livestock farms, high adoption of Agri-tech solutions, and government support for digital agriculture.

Europe (Germany, U.K., France, Italy, Spain, Russia, etc.)

Strong focus on animal welfare regulations and sustainable dairy and meat production.

Widespread adoption of AI-powered farm management tools.

Asia-Pacific (China, India, Japan, Southeast Asia, etc.)

Fastest-growing market due to increasing livestock population and rising demand for dairy and meat products.

Government initiatives promoting smart farming solutions and digital agriculture.

South America (Brazil, Argentina, etc.)

Growing investments in precision livestock farming to enhance meat production and export quality.

Middle East & Africa (Saudi Arabia, South Africa, etc.)

Increasing adoption of AI-based monitoring solutions in large-scale cattle and poultry farms.

Competitive Landscape

Key players in the global livestock monitoring market include:

Major Companies & Their Offerings

Company Name

Key Offerings

Delaval

Automated milking systems, precision feeding solutions

Gea Group

Smart farming solutions, herd management software

Afimilk

IoT-enabled dairy monitoring, AI-based fertility tracking

Boumatic

Robotic milking, automated dairy herd management

SCR Dairy

Smart cow collars, heat detection systems

Dairymaster

Digital dairy monitoring, cloud-based herd analytics

Lely Holding

Robotics for automated feeding, milking, and manure management

Sum-It Computer Systems

Farm management software, data analytics

Valley Agriculture Software

AI-based livestock tracking and performance monitoring

Infovet

Digital livestock health monitoring solutions

Recent Developments & Market Strategies

AI-Powered Livestock Monitoring Solutions: Companies are integrating AI-driven predictive analytics to detect diseases, stress levels, and fertility cycles in livestock.

IoT-Based Smart Farming Innovations: RFID, GPS trackers, and cloud-based herd management platforms are gaining traction.

Mergers & Acquisitions: Major players are expanding their market presence through strategic partnerships and acquisitions.

Get enquiry before buying @ https://www.statsandresearch.com/enquire-before/26406-global-livestock-monitoring-market

0 notes

Text

Why Logistics Companies Need Freight Forwarding Software for Global Operations

In today’s fast-paced global economy, logistics companies face the challenge of handling complex supply chains, cross-border regulations, fluctuating market demands, and increasing customer expectations. Traditional freight management methods can no longer keep up with the speed and accuracy required for seamless global operations. This is where Freight Forwarding Software plays a crucial role in transforming logistics businesses.

From automating workflows to enhancing real-time tracking, Freight Forwarding Software is an essential tool for modern logistics companies looking to scale their operations globally. In this blog, we’ll explore why logistics companies need freight forwarding software and how it can optimize global operations.

1. Automation and Process Optimization

Freight forwarding involves multiple tasks, including documentation, shipment tracking, customs clearance, invoicing, and compliance checks. Manually handling these tasks can lead to errors, delays, and inefficiencies. Freight forwarding software automates these processes, ensuring accuracy, reducing paperwork, and increasing productivity.

With automated workflows, logistics companies can handle booking confirmations, shipment scheduling, and tracking updates seamlessly, saving time and operational costs.

2. Compliance and Documentation Management

International trade involves complex compliance regulations across different countries, including customs clearance, tax policies, import/export documentation, and safety standards. Managing these manually can result in costly mistakes and legal issues.

A robust freight forwarding software provides:

Automated document generation (e.g., Bill of Lading, Airway Bills, Commercial Invoices)

Customs compliance integration to ensure shipments adhere to global trade regulations

Digital document storage to avoid paperwork loss and delays

With these features, logistics companies can reduce compliance risks and streamline international shipping processes efficiently.

3. Cost Efficiency and Profit Maximization

Cost management is a major concern for logistics companies handling global shipments. Freight forwarding software helps businesses reduce operational expenses and maximize profitability by:

Optimizing freight rates through automated carrier selection

Reducing manual labor costs by automating data entry and reporting

Minimizing risks of delays and penalties due to compliance errors

By integrating freight forwarding software, companies can cut costs, enhance efficiency, and improve overall profit margins.

4. Scalability for Global Expansion

As logistics companies expand to new markets, they require scalable solutions to handle increased shipment volumes, diverse shipping modes, and multi-country operations. Freight forwarding software provides:

Multi-location and multi-currency support

Cloud-based access for global teams

AI-powered analytics for business insights

These features allow logistics companies to seamlessly scale their operations while maintaining control over their global supply chain.

5. Real-Time Shipment Tracking and Visibility

Global logistics demand real-time shipment tracking to provide customers and stakeholders with accurate updates. Freight forwarding software integrates with GPS, IoT, and cloud-based tracking systems, offering complete visibility into shipment status.

With features like:

Live tracking dashboards

Automated alerts and notifications

ETA predictions and route optimization

Logistics companies can proactively address delays, rerouting needs, or any disruptions in the supply chain, ensuring smooth global operations.

Conclusion

In a world where logistics and supply chain management are becoming increasingly complex, freight forwarding software is no longer optional—it’s a necessity. From automation and compliance management to real-time tracking and cost optimization, the right software empowers logistics companies to stay competitive, reduce inefficiencies, and expand globally.

If your logistics business aims to scale and streamline global operations, investing in freight forwarding software is the key to success.

Would you like help selecting the best freight forwarding software for your business? Let’s discuss your requirements!

#logistics software#freight software#freight forwarding software#software for freight forwarding software

1 note

·

View note

Text

3pl Companies Near Me

3pl Companies Near Me https://modernlogisticsusa.com/3pl-companies-near-me/ United States

3PL Companies Near Me: Why You Need Them, Applications, and Benefits In today's fast-paced business environment, managing logistics and supply chain operations efficiently is crucial for success. Whether you're an e-commerce business, a manufacturer, or a retailer, partnering with 3PL companies near me can streamline operations, reduce costs, and improve efficiency. Third-party logistics (3PL) providers offer warehousing, distribution, freight management, and order fulfillment services, helping businesses scale operations without the need for extensive infrastructure. This article explores why 3PL services are essential, their various applications, and the benefits of outsourcing logistics.

Why You Need 3PL Companies Near Me Businesses of all sizes rely on third-party logistics providers to handle their supply chain operations efficiently. Here’s why hiring a 3PL company near me is beneficial:

Efficient Warehousing and Inventory Management 3PL providers offer state-of-the-art storage facilities, helping businesses manage inventory without the need for costly warehousing space.

Faster and More Reliable Shipping With strategically located fulfillment centers, 3PL companies can reduce shipping times and optimize delivery routes, improving customer satisfaction.

Cost Savings and Reduced Overhead Outsourcing logistics eliminates the need for investing in storage, transportation, and fulfillment infrastructure, leading to significant cost savings.

Scalability for Business Growth A 3PL provider allows businesses to scale operations up or down based on demand without committing to long-term investments in logistics.

Expertise in Supply Chain and Compliance 3PL companies have in-depth knowledge of industry regulations, customs compliance, and freight management, reducing the risk of legal and logistical issues.

Focus on Core Business Operations By outsourcing logistics, businesses can concentrate on product development, sales, and marketing instead of managing complex supply chain processes.

Advanced Technology and Real-Time Tracking 3PL providers use modern logistics software, AI-driven inventory management, and real-time shipment tracking to enhance efficiency and accuracy.

Applications of 3PL Services 3PL services cater to a wide range of industries, including retail, e-commerce, healthcare, and manufacturing.

E-Commerce Fulfillment With the growth of online shopping, e-commerce businesses need reliable logistics partners to handle: • Warehousing and inventory management • Picking, packing, and order fulfillment • Returns processing and customer support

Retail and Wholesale Distribution Retailers and wholesalers depend on 3PL services for efficient inventory management, order processing, and store distribution.

Freight and Transportation Management 3PL providers handle domestic and international freight shipping, including: • Less Than Truckload (LTL) and Full Truckload (FTL) shipping • Freight forwarding and intermodal transportation • Last-mile delivery solutions

Cold Storage and Food Logistics Businesses that deal with perishable goods benefit from temperature-controlled warehousing and distribution services.

Manufacturing and Industrial Logistics Manufacturers rely on 3PL companies for raw material transportation, just-in-time inventory management, and finished goods distribution.

Cross-Docking and Transloading 3PL providers help businesses move shipments quickly through ports and distribution centers, reducing storage costs and delivery times.

International Shipping and Customs Clearance For businesses expanding globally, 3PL companies assist with customs brokerage, import/export regulations, and international freight coordination.

Benefits of Partnering with a 3PL Provider Hiring a 3PL company near me offers numerous advantages, making logistics and supply chain management more efficient.

Cost Savings and Increased Profitability Outsourcing logistics reduces the need for expensive storage facilities, equipment, and labor, leading to long-term savings.

Faster and More Accurate Order Fulfillment 3PL providers use automated systems and optimized logistics strategies to ensure accurate and timely order processing.

Access to Advanced Technology Many 3PL companies use AI-driven analytics, real-time tracking, and warehouse management systems (WMS) to improve efficiency.

Compliance with Regulations Experienced 3PL providers handle legal requirements, customs clearance, and safety regulations, reducing risks for businesses.

Greater Flexibility and Scalability Businesses can adjust storage, shipping, and fulfillment services based on seasonal demand and market fluctuations.

Improved Customer Satisfaction Faster deliveries, accurate order fulfillment, and better return management enhance the overall customer experience.

Support for Global Supply Chains For businesses expanding internationally, 3PL providers offer seamless global logistics solutions and supply chain optimization.

Conclusion Searching for 3PL companies near me is the first step toward optimizing your logistics and supply chain operations. Whether you need warehousing, transportation management, or order fulfillment services, partnering with a trusted 3PL provider offers efficiency, cost savings, and scalability. By outsourcing logistics to experts, businesses can focus on growth while ensuring seamless supply chain operations. Whether you're a small startup or a large enterprise, a 3PL provider can help you improve efficiency, reduce costs, and enhance customer satisfaction.

1 note

·

View note

Text

Enterprise Asset Management Market Size And Share Report, 2030

Enterprise Asset Management Market Growth & Trends

The global enterprise asset management market size is estimated to reach a market size of USD 19.68 billion by 2030 and expand at a CAGR of 16.9% from 2023 to 2030, according to a new study by Grand View Research, Inc. The significant market growth can be attributed to the rising technical advancements, the growing acceptance of advanced technologies for developing asset lifecycles, and the advent of innovative digital technologies across industrial verticals, such as cloud-based EAM. For instance, in April 2023, Ernst & Young LLP, a consulting company, announced a partnership with Asset Lifecycle Intelligence, a division of Hexagon AB, to offer asset performance management and enterprise asset management (EAM) technologies. Through the partnership, EY would help its customers track, monitor, and extract value from assets while mitigating risks such as unplanned costs and operational downtime.

To provide EAM and Asset Performance Management (APM) technologies as part of digital transformation and cloud migration initiatives through innovation and solution expertise. For clients aiming to address business challenges and issues regarding assets, this alliance employs EAM and APM service offerings. To promote the sustainability of digital realities and promote autonomous futures, this partnership draws together technological expertise in sustainability, digital twin, cyber, supply chain, and manufacturing execution systems, along with installation and upgrade assistance.

Cloud EAM deployment eliminates the need for extensive on-premises hardware and reduces IT infrastructure costs, allowing organizations to allocate resources more efficiently. Furthermore, cloud deployment offloads maintenance tasks, such as software updates and security patches, to the service provider, allowing the organization's IT team to focus on core business activities. For instance, in November 2022, as global's an IT services provider, announced a partnership with Dynaway, a provider of Microsoft Dynamics platform-based enterprise asset management. Through the partnership, the former company will add Dynaway’s EAM solution to its offering portfolio. The new solution would help sa.global’s clients to improve asset performance with predictive maintenance and create connected ecosystems that boost productivity, efficiency, and quality.

Several enterprises worldwide were impacted by the pandemic's breakout and the following lockdowns, travel bans, limits on people's liberty of movement, and company closures. Numerous businesses worldwide have adopted enterprise asset management solutions to manage assets, equipment, IT systems, and other resources efficiently and effectively, avoid potential hardware or machine failures, cut downtime, and maintain continuous operations. Several companies allowed remote working as part of their efforts to preserve and defend their employees' well-being following the pandemic outbreak, which resulted in a persistent demand for EAM solutions. Due to this factor, demand for enterprise asset management solutions is expected to increase notably in the forecast period.

Organizations across the world are increasingly concerned about data security at the time of implementation of an advanced IT or cloud-based EAM solution. Several manufacturing organizations wanting to improve business efficiency, asset management, and industrial operations believe security and compliance as the main barriers restricting the deployment of EAM solutions. For instance, in October 2022, Oracle launched an asset-based customer service for Oracle Fusion Cloud Applications Package to assist organizations in improving service effectiveness and customer experience.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/enterprise-asset-management-market-report

Enterprise Asset Management Market Report Highlights

The cloud service segment is anticipated to emerge as the fastest-growing solution segment over the forecast period. Organizations that want to control customer and company information security tend to prefer the on-premises version of EAM. A company's internal IT team is responsible for setting up, hosting, and managing this deployment

The small & medium enterprise segment is anticipated to emerge as the fastest-growing solution segment from 2023-2030. SMEs are starting to invest in cloud-based EAM software and transition to upgraded solutions. It has a low initial investment requirement, enables users to manage assets remotely, and allows for mobile usage, giving workers more freedom in their jobs

The government segment is anticipated to emerge as the fastest-growing solution segment over the forecast period. Government organizations can boost accountability and transparency throughout the entire organization and extend the life of their most valuable assets by implementing EAM software

The APAC market is estimated to be the fastest-growing segment, offering lucrative growth opportunities for the industry players. Businesses in APAC countries such as India still in the development stage are focusing on globalization to build a regional economic outlook and get traction in the local EAM market

Enterprise Asset Management Market Segmentation

Grand View Research has segmented the global enterprise asset management market based on deployment, enterprise size, end use, and region.

Enterprise Asset Management (EAM) Deployment Outlook (Revenue, USD Million; 2018 - 2030)

Cloud

On-premise

Enterprise Asset Management (EAM) Enterprise Size Outlook (Revenue, USD Million; 2018 - 2030)

Large Enterprise

Small & Medium Enterprise

Enterprise Asset Management (EAM) End Use Outlook (Revenue, USD Million; 2018 - 2030)

Manufacturing

Facility Management

Healthcare

Education

Government

Others

Enterprise Asset Management (EAM) Regional Outlook (Revenue, USD Billion; 2018 - 2030)

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

List of The Key Player in the Enterprise Asset Management Market

Aptean

AssetWorks, LLC

CGI, Inc.

IFS AB

Infor

International Business Machines (IBM) Corporation

Oracle Corporation

PcsInfinity (Asset Infinity)

Sage Group PLC

SAP SE

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/enterprise-asset-management-market-report

#Enterprise Asset Management Market Size#Enterprise Asset Management Market Share#Enterprise Asset Management Market Trends

0 notes

Text

Why Manufacturers Grow Faster With ERP Software

Introduction:

In the ever-evolving landscape of manufacturing, staying ahead of the competition requires more than just producing quality products. It demands efficient processes, streamlined operations, and the ability to adapt to changing market dynamics. This is where ERP (Enterprise Resource Planning) software steps in as a game-changer for manufacturers. In this blog, we'll delve into the reasons why manufacturers experience accelerated growth with ERP software and explore the significance of key ERP modules designed for the manufacturing industry. Let's unlock the potential of the best manufacturing ERP software and understand how it propels growth.

Understanding ERP Modules for Manufacturing Industry:

1. Supply Chain Management:

Effective supply chain management is at the core of manufacturing success. ERP modules for manufacturing industry streamline supply chain processes by providing real-time visibility into inventory levels, order status, and supplier relationships. Manufacturers can optimize procurement, reduce lead times, and enhance overall supply chain efficiency.

2. Production Planning and Scheduling:

Efficient production planning and scheduling are essential for meeting customer demands and minimizing downtime. ERP software enables manufacturers to create realistic production schedules, allocate resources effectively, and adjust plans dynamically in response to changing demand. This results in improved production efficiency and timely delivery of products.

3. Quality Control:

Maintaining consistent product quality is a non-negotiable aspect of manufacturing. ERP modules for quality control allow manufacturers to monitor production processes in real-time, track defects, and enforce adherence to quality standards. This not only ensures the delivery of high-quality products but also reduces waste and rework costs.

4. Inventory Management:

Managing inventory effectively is a delicate balancing act. ERP software provides manufacturers with tools to optimize inventory levels, track stock movements, and minimize carrying costs. With real-time insights into inventory status, manufacturers can prevent stockouts, reduce excess inventory, and enhance overall supply chain efficiency.

Manufacturing Enterprise Resource Planning Software: Unleashing Growth Potential

1. Streamlined Communication:

Effective communication is crucial for seamless operations. Manufacturing ERP software centralizes communication channels, allowing different departments to share information in real-time. This not only reduces the risk of miscommunication but also fosters collaboration among teams, leading to improved overall efficiency.

2. Data-Driven Decision-Making:

In the fast-paced world of manufacturing, decisions need to be swift and well-informed. ERP software aggregates data from various business processes, providing manufacturers with actionable insights. Data-driven decision-making becomes a reality, enabling manufacturers to respond proactively to market trends, customer demands, and operational challenges.

3. Scalability for Growth:

Growth is a constant objective for manufacturers. The best ERP for the manufacturing industry is designed with scalability in mind. As businesses expand, ERP systems can easily accommodate increased data volume, users, and additional functionalities. This scalability ensures that the ERP solution grows with the manufacturing enterprise, supporting its evolving needs.

4. Enhanced Customer Relationship Management (CRM):

Customer satisfaction is a key driver of growth. Manufacturing ERP software often includes CRM modules that allow manufacturers to manage customer relationships effectively. From order processing to after-sales support, ERP systems help manufacturers deliver exceptional customer experiences, fostering customer loyalty and driving growth.

Best ERP for Manufacturing Industry: Navigating Toward Success

1. Tailored Solutions for Industry Needs:

The best ERP for the manufacturing industry goes beyond generic solutions. It offers modules specifically designed to address the unique challenges and requirements of manufacturing operations. From managing complex bills of materials to handling production workflows, the best ERP software is tailored to the intricacies of the manufacturing sector.

2. Real-Time Reporting and Analytics:

Timely and accurate reporting is a cornerstone of effective decision-making. The best manufacturing ERP software provides robust reporting and analytics capabilities, allowing manufacturers to generate custom reports, track key performance indicators (KPIs), and gain insights into operational efficiency. This empowers manufacturers to identify areas for improvement and implement strategic changes.

3. Compliance and Regulatory Support:

Compliance with industry regulations is non-negotiable for manufacturers. The best ERP solutions for manufacturing industry include features that help businesses adhere to regulatory requirements. This not only ensures legal compliance but also mitigates the risk of penalties and reputational damage.

4. User-Friendly Interfaces:

User adoption is critical for the success of any ERP implementation. The best ERP modules for manufacturing industry prioritize user-friendly interfaces, making it easier for employees to navigate the system and perform their tasks. Intuitive interfaces contribute to smoother onboarding processes and overall system usability.

Conclusion:

In the fast-paced world of manufacturing, growth is not just a goal; it's a necessity. ERP software emerges as a strategic ally for manufacturers, propelling them toward accelerated growth by optimizing processes, fostering efficiency, and enabling informed decision-making. From the essential ERP modules for the manufacturing industry to the features that make the best ERP solutions stand out, manufacturers can unlock their full growth potential with the right ERP software. Embrace the power of ERP, and witness your manufacturing enterprise soar to new heights of success.

#ERP Modules for Manufacturing Industry#Manufacturing Enterprise Resource Planning Software#Best Manufacturing ERP Software#Best ERP for Manufacturing Industry#ERP Software for Manufacturing Industry#ERP System for Manufacturing Industry#ERP for Software Development Company#ERP Solutions for Manufacturing#India

6 notes

·

View notes

Text

Latin America GIS Solutions Market Outlook and Forecast 2025-2032

The Latin America GIS Solutions Market was valued at US$ 864 million in 2024 and is projected to reach US$ 1.25 billion by 2030, at a CAGR of 6.4% during the forecast period 2024-2030.

Geographic Information System Solutions encompass specialized software platforms, applications, and integrated systems designed for spatial data management, analysis, and visualization. These solutions include mapping tools, spatial analytics engines, remote sensing applications, and customized GIS platforms for specific industry verticals. The technology incorporates advanced features such as 3D modeling, real-time data processing, mobile integration, and cloud-based services, all tailored to meet diverse geographic information management needs across multiple sectors.

The Latin American GIS Solutions market demonstrates robust growth driven by digital transformation initiatives:nnTechnology Integration:n- Cloud-based solutions adoption rate: 42%n- Mobile GIS implementation: 38%n- AI/ML integration in GIS: 35%n- IoT sensor integration: 28%nnSector-wise Adoption:n- Government sector: 45%n- Infrastructure development: 32%n- Natural resource management: 28%n- Urban planning: 25%nnRegional Developments:n- Brazil leads with 48% market sharen- Mexico's smart city initiatives driving 22% growthn- Colombia's infrastructure projects expanding 18%n- Chile's mining sector adoption up 15%nnKey Growth Drivers:n- Digital transformation initiativesn- Smart city developmentsn- Environmental monitoring needsn- Infrastructure planning requirements

Download a Free Sample Report PDF @ https://www.24chemicalresearch.com/download-sample/286432/latin-america-gis-solutions-market-2025-2032-533

Report Includes

This report is an essential reference for who looks for detailed information on Latin America GIS Solutions. The report covers data on Latin America markets including historical and future trends for supply, market size, prices, trading, competition and value chain as well as Latin America major vendors¡¯ information. In addition to the data part, the report also provides overview of GIS Solutions, including classification, application, manufacturing technology, industry chain analysis and latest market dynamics. Finally, a customization report in order to meet user's requirements is also available.